Eccentric TSD

Cowl disc type Impellers are the most commonly used to perform emulsions. It’s efficiency is the

result of a compromise between sharing performance and circulation according to the desired

size of particles.

The unique dispersion head is consist of a slotted rotor / cowl operating inside of slotted stator /

cowl. The cowl disc turning at high speed, functions as centrifugal pump, drawing materials from

above and below and hurling it off the slot tips at high speed, breaking it down to its smallest

particle size. It has ability to quickly reduce agglomerates to their original or ultimate particle

size. Blending and dispersing them with low to high viscosity liquid vehicle and wetting them out

to create stable dispersions.

Batch High Speed Dispersing

► Batch dispersers work according to the principle of a cowls system

with a relatively high shear energy.

► By the centrifugal forces in the cowl disc a circulation in the vessel can be attached.

► By impact and shear action a strong dispersing effect is reached during the passage

through the Cowl disc area.

► During dispersing, the product has to pass through the system again and again.

► This result is very fine suspensions, wet ground products or emulsions.

► By an appropriate selection of the energy and dispersing tool the system may be

adapted to individual processing steps, viscosity and processing aim.

► Controlling the speed by a frequency converter extends the field of applications for

different products and volumes.

► Similar to a fast rotating mixing system, the batch disperser is installed on to the top or in

the bottom of a vessel.

► Batch disperser are used for small to medium sized batches.

► The limit is reached, when the product in the vessel does not circulate anymore because

of the limitation in viscosity and volume.

► Viscosity over 3000 mPas normally can’t be treated economically anymore, in this case

an inline dispersing system should be foreseen.

INFORMATION AND PRINCIPLE

► The machines are delivered with mechanical seal systems either in single action or

double action execution. When selecting a double action mechanical seal, the system is

being cooled and lubricated with a non-pressurized system in-between the product side

and the atmospheric side.

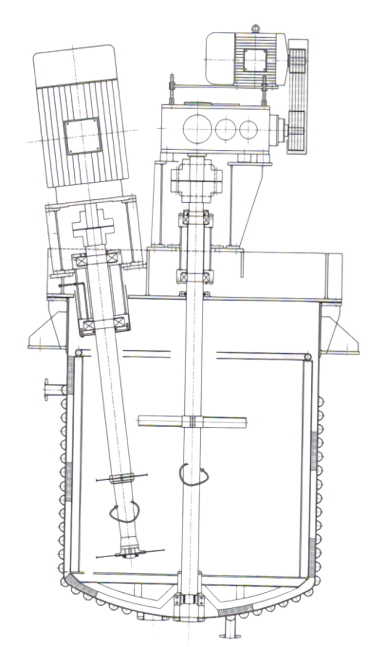

► A special design of the batch dispersing machine is the installation into the bottom of a

tank.

► This system is mainly selected in combination with an anchor stirrer and/or other

centrically installed stirring elements.

► In this case, the disperser handles all dispersing and emulsifying task, while the stirrer

takes care for the required circulation in the tank.

► Emulsions

Narrow droplet spectrum and short treatment times for vegetable and animal

components of type W/O and O/W.

► Pigment Suspension

Good wetting of pigments and breaking of agglomerates results in a maximum

concentration of dry contents

► Dilution of SLES

By individually and controlled dosing the different components, an absolutely lump-free

mixture can be achieved.

► Homogenizing

Pastes, gels, Pectin, CMC powder and similar products are being dispersed absolutely

lump-free.

► Dissolving

Colloidal and real solutions may be produced in shortest time. the energy brought into

the system by the dispersing elements accelerate the dissolving process.

► Other applications are : extracting, splitting up fibers and disintegration of products.