Agitated Nutsch Filter

Chemical Process Plants and Equipment's

Designed to operate under either on vacuum or pressure in batch operated industries such as fine chemicals, dyes, pharmaceuticals and particles.

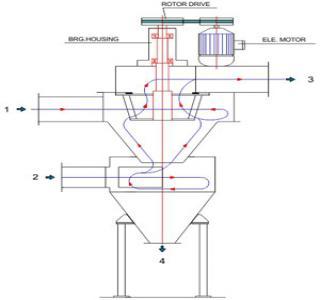

Nutsch Filter is designed to perform a multitude of tasks including reaction filtration, cake washing and thermal drying on a single unit.

Nutsch Filter is normally consisting of the vessel, the filter floor and cloth, woven mesh screen or sintered metal plate medium, the re-slurry arms for cake washing and smoothing and the cake discharge mechanism.

The Vessel: Being batch system vessel volume is designed to accommodate total volume of slurry charge. Normally designed to operate at 2-3 kg./cm. Sq. pressure and vacuum operation.

The vessel top dished end cover support agitator drive assembly as well hydraulic or mechanical system for lowering and raising of the rotating augur and re-slurry paddle arms.

Shell will be provided with limpet coil or jacket for heating or cooling requirements.

The filter flow and filtering medium consisting of a densely perforated plate sufficiently strong to hold the cake weight and pressure that is exerted on the cake’s surface.