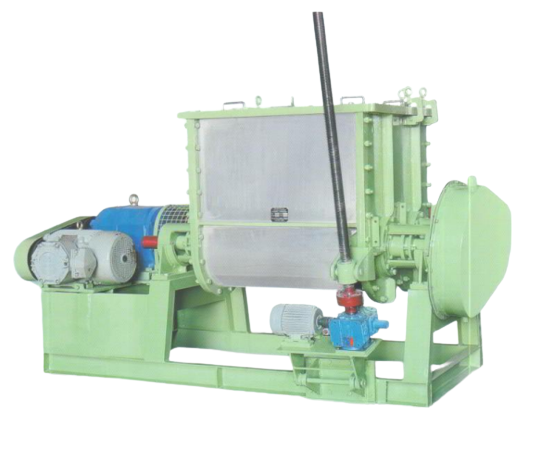

Sigma Mixer

The sigma mixture consists of "W" shaped container. Sigma blade mixtures are engineered specifically for kneading mixing and homogenizing wet and highly viscous products. It includes two blades that rotate toward each other at same or differential speeds. Each blade moves the material in opposite directions thereby providing excellent cross mixing of all raw materials. The blades pass the through walls and each other at close clearances. This close clearance action provides a shearing and tearing action that is beneficial to the size reduction of solids such as rubber and plastic pellets.

Once the mixing cycle is complete the trough of the mixer is titled and the mixture is discharged. Motorized extruder can be provided for discharging sticky materials instead of tilting mechanism.

Options: Mechanical or hydraulic drive system.

1. Easy discharge by lifting the container. Bottom sliding valves/bottom gates/flush bottom gate

valve.

2. Jacketed shell for heating or cooling by steam, oil,

water etc. (Can be offered for vacuum or pressure

application).

3. Working facility with vacuum or pressure.

4. Tilting by hand lever/electric arrangements/ hydraulic system.

Capacity and Size:

1. Available in working capacities from 5 litters to 2500 liters.

2. Custom Size available as per requirement